- Types of contaminants that can be removed with laser cleaning

- Safety precautions for using laser cleaning on vinyl surfaces

- Environmental impact of laser cleaning compared to chemical cleaning

- Challenges and limitations of laser cleaning for vinyl surfaces

- The impact of laser cleaning on the texture of vinyl surfaces

- The impact of laser cleaning on the flexibility of vinyl surfaces

- The future of laser cleaning technology for vinyl surfaces

- Comparison of laser cleaning with traditional cleaning methods

Types of contaminants that can be removed with laser cleaning

- Rust: Laser cleaning can effectively remove rust from metal surfaces, restoring them to their original condition.

- Paint: Paint can be easily removed with laser cleaning, making it a popular method for stripping paint from surfaces.

- Oil and grease: Laser cleaning can effectively remove oil and grease from surfaces, making it ideal for cleaning industrial equipment.

- Corrosion: Laser cleaning can remove corrosion from metal surfaces, extending their lifespan and preventing further damage.

- Scale: Scale buildup on surfaces can be easily removed with laser cleaning, restoring the surface to its original state.

- Adhesives: Laser cleaning can effectively remove adhesives from surfaces, making it a versatile method for cleaning various materials.

Overall, laser cleaning is a versatile and efficient method for removing a wide range of contaminants from different surfaces. Whether you need to remove rust, paint, oil, grease, corrosion, scale, or adhesives, laser cleaning can provide a fast and effective solution.

Hashtags: #laser #cleaning #contaminants #rust #paint #oil #grease #corrosion #scale #adhesives

Keywords: laser cleaning, contaminants, rust, paint, oil, grease, corrosion, scale, adhesives

Long-tail phrases: types of contaminants removed with laser cleaning, benefits of laser cleaning for surface restoration, applications of laser cleaning in industrial settings

Safety precautions for using laser cleaning on vinyl surfaces

- Wear protective eyewear: Laser beams can be harmful to the eyes, so it is important to wear appropriate eye protection when using laser cleaning equipment.

- Avoid direct contact with the laser beam: Direct exposure to the laser beam can cause burns or other injuries. Make sure to keep a safe distance from the beam and avoid looking directly at it.

- Use proper ventilation: Laser cleaning can produce fumes and smoke, so it is important to work in a well-ventilated area to avoid inhaling harmful chemicals.

- Keep flammable materials away: Laser cleaning equipment can generate heat, so it is important to keep flammable materials away from the work area to prevent fires.

- Follow manufacturer’s instructions: Make sure to read and follow the manufacturer’s instructions for the specific laser cleaning equipment being used to ensure safe and effective operation.

By following these safety precautions, you can ensure that laser cleaning is a safe and effective method for cleaning vinyl surfaces without causing harm to yourself or the surface being cleaned.

#safety #precautions #laser #cleaning #vinyl #surfaces

frazy kluczowe:

– Bezpieczeństwo podczas czyszczenia laserowego

– Zasady bezpieczeństwa podczas czyszczenia laserem powierzchni winylowych

– Laserowe czyszczenie winylu: jak zachować bezpieczeństwo

Environmental impact of laser cleaning compared to chemical cleaning

Laser Cleaning

Laser cleaning is a non-contact method that uses a high-energy laser beam to remove contaminants from surfaces. This method is environmentally friendly because it does not require the use of chemicals. The only waste produced during laser cleaning is the removed contaminants, which can be easily disposed of or recycled. Additionally, laser cleaning does not produce any harmful emissions or by-products, making it a clean and sustainable option for surface cleaning.

Chemical Cleaning

Chemical cleaning, on the other hand, involves the use of harsh chemicals to remove contaminants from surfaces. While this method is effective, it can have a negative impact on the environment. The chemicals used in the cleaning process can be toxic and harmful to both humans and the environment. Additionally, the disposal of chemical waste can pollute water sources and soil, leading to environmental contamination.

Comparison

When comparing the environmental impact of laser cleaning to chemical cleaning, it is clear that laser cleaning is the more sustainable option. Laser cleaning does not produce any harmful emissions or by-products, and it does not require the use of toxic chemicals. This makes it a cleaner and safer method for surface cleaning, with minimal impact on the environment.

Conclusion

In conclusion, laser cleaning is a more environmentally friendly option compared to chemical cleaning. It produces less waste, does not emit harmful emissions, and does not require the use of toxic chemicals. By choosing laser cleaning over chemical cleaning, we can reduce our impact on the environment and promote sustainability in surface cleaning practices.

#environment #laser #cleaning #chemical #impact #sustainability

frazy kluczowe:

– environmental impact of laser cleaning

– comparison of laser cleaning and chemical cleaning

– sustainable surface cleaning methods

– reducing environmental impact with laser cleaning

– promoting sustainability in cleaning practices

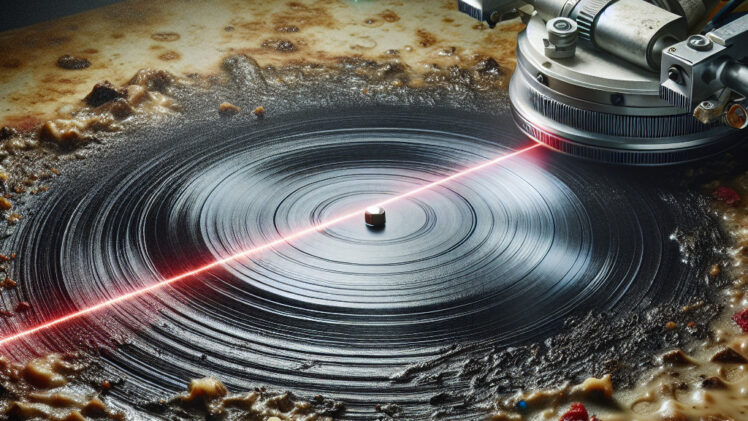

Challenges and limitations of laser cleaning for vinyl surfaces

Laser cleaning has emerged as a promising alternative for cleaning vinyl surfaces. This non-contact method uses a high-energy laser beam to remove contaminants from the surface without damaging the underlying material. However, there are several challenges and limitations associated with laser cleaning for vinyl surfaces.

Challenges:

– Limited effectiveness on certain types of contaminants: Laser cleaning may not be as effective on certain types of contaminants, such as oil-based stains or deeply embedded dirt.

– Potential damage to the surface: High-energy laser beams can potentially damage the surface of the vinyl if not used properly.

– Cost: Laser cleaning equipment can be expensive to purchase and maintain, making it less accessible for smaller businesses.

– Safety concerns: Laser cleaning requires proper training and safety precautions to prevent accidents and injuries.

Limitations:

– Surface temperature: Laser cleaning can generate heat, which may affect the temperature of the vinyl surface and potentially cause damage.

– Surface texture: Laser cleaning may not be suitable for all types of vinyl surfaces, especially those with intricate textures or patterns.

– Size limitations: Laser cleaning equipment may have size limitations, making it difficult to clean large vinyl surfaces efficiently.

In conclusion, while laser cleaning offers many benefits for cleaning vinyl surfaces, there are also challenges and limitations that need to be considered. Proper training, equipment maintenance, and safety precautions are essential to ensure effective and safe cleaning results.

#vinylsurfaces #lasercleaning #cleaningtechnology #surfacecleaning

frazy kluczowe:

– laser cleaning for vinyl surfaces challenges and limitations

– limitations and challenges of laser cleaning for vinyl surfaces

The impact of laser cleaning on the texture of vinyl surfaces

It is important for users of laser cleaning technology to carefully consider the impact on the texture of vinyl surfaces before using this method. By adjusting the power and intensity of the laser, it is possible to minimize the negative effects on texture while still achieving effective cleaning results. Additionally, using protective coatings or barriers can help to prevent damage to the surface during the cleaning process.

In conclusion, laser cleaning can have a significant impact on the texture of vinyl surfaces. By understanding the potential effects of this technology and taking appropriate precautions, it is possible to achieve clean, visually appealing surfaces without compromising texture.

- laser cleaning

- texture

- vinyl surfaces

- impact

- technology

- positive effects on texture

- negative effects on texture

- adjusting laser power

- protective coatings

#laser #cleaning #texture #vinyl #surfaces #impact #technology

The impact of laser cleaning on the flexibility of vinyl surfaces

The flexibility of vinyl surfaces is crucial for their performance in various applications, such as automotive interiors, upholstery, and signage. When contaminants build up on the surface of vinyl, they can cause the material to become stiff and less pliable. This can lead to cracking, tearing, or other forms of damage that compromise the integrity of the vinyl surface.

Laser cleaning offers a solution for restoring the flexibility of vinyl surfaces without causing any damage. By removing contaminants and restoring the surface to its original condition, laser cleaning can extend the lifespan of vinyl surfaces and improve their overall performance. This can result in cost savings for businesses that rely on vinyl materials for their products or services.

Furthermore, laser cleaning is a sustainable and eco-friendly solution for maintaining vinyl surfaces. Unlike traditional cleaning methods that generate waste or require the use of harmful chemicals, laser cleaning is a clean and efficient process that does not produce any byproducts. This makes it an ideal choice for businesses that prioritize environmental sustainability and want to reduce their carbon footprint.

In conclusion, laser cleaning has a significant impact on the flexibility of vinyl surfaces. By removing contaminants and restoring the surface to its original condition, laser cleaning can improve the performance and longevity of vinyl materials. This innovative cleaning method offers a non-contact and environmentally friendly solution for maintaining vinyl surfaces in various industries.

- vinyl surfaces

- laser cleaning

- flexibility

- performance

- contaminants

- environmentally friendly

- impact of laser cleaning on vinyl surfaces

- benefits of laser cleaning for vinyl materials

- sustainable cleaning solutions for vinyl surfaces

- improving flexibility with laser cleaning

- cost-effective maintenance of vinyl materials

#vinylsurfaces, #lasercleaning, #flexibility, #performance, #contaminants, #environmentallyfriendly

The future of laser cleaning technology for vinyl surfaces

Benefits of laser cleaning technology for vinyl surfaces:

– Non-abrasive: Laser cleaning is a non-contact process that does not require the use of harsh chemicals or abrasive materials, making it ideal for delicate vinyl surfaces.

– Precision: Laser cleaning can be precisely controlled to target specific areas, ensuring thorough cleaning without causing damage.

– Efficiency: Laser cleaning is a fast and efficient process that can remove contaminants quickly and effectively.

– Environmentally friendly: Laser cleaning does not produce any harmful byproducts or waste, making it a sustainable cleaning solution.

With these benefits in mind, looks bright. As technology continues to advance, we can expect to see even more powerful and efficient laser cleaning systems that are capable of tackling a wider range of contaminants. Additionally, improvements in laser technology may lead to the development of portable and handheld laser cleaning devices, making it easier for users to clean vinyl surfaces on the go.

Overall, laser cleaning technology holds great promise for the future of vinyl surface cleaning. With its non-abrasive nature, precision, efficiency, and environmental friendliness, laser cleaning is poised to become the go-to cleaning solution for vinyl surfaces in the years to come.

#laser #cleaning #technology #vinyl #surfaces

frazy kluczowe:

– Innovative laser cleaning technology for vinyl surfaces

– Efficient and environmentally friendly cleaning solution for vinyl

– The future of cleaning technology: laser cleaning for vinyl surfaces

Comparison of laser cleaning with traditional cleaning methods

Laser Cleaning

Laser cleaning is a non-contact cleaning method that uses a high-powered laser beam to remove contaminants from surfaces. The laser beam is directed at the surface to be cleaned, and the energy from the laser vaporizes the contaminants, leaving behind a clean surface. Laser cleaning is effective at removing a wide range of contaminants, including rust, paint, grease, and dirt. It is also environmentally friendly, as it does not require the use of chemicals or solvents.

Traditional Cleaning Methods

Traditional cleaning methods, such as scrubbing, sandblasting, and chemical cleaning, have been used for centuries to remove contaminants from surfaces. While these methods can be effective, they often require the use of harsh chemicals and solvents, which can be harmful to the environment and to the health of those performing the cleaning. Traditional cleaning methods can also be time-consuming and labor-intensive, especially when cleaning large or complex surfaces.

Advantages of Laser Cleaning

- Non-contact cleaning method

- Environmentally friendly

- Effective at removing a wide range of contaminants

- Does not require the use of chemicals or solvents

- Can be used on a variety of surfaces, including metal, plastic, and glass

Disadvantages of Laser Cleaning

- High initial cost of equipment

- Requires specialized training to operate

- May not be as effective on certain types of contaminants

- Can be slower than traditional cleaning methods for large surfaces

Overall, laser cleaning offers a number of advantages over traditional cleaning methods, including its non-contact nature, environmental friendliness, and effectiveness at removing contaminants. However, it also has some disadvantages, such as the high initial cost of equipment and the need for specialized training. Ultimately, the choice between laser cleaning and traditional cleaning methods will depend on the specific cleaning requirements and budget constraints of the user.

Hashtags: #lasercleaning #traditionalcleaning #cleaningmethods #environmentallyfriendly

Keywords: laser cleaning, traditional cleaning methods, non-contact cleaning, environmentally friendly

Long-tail phrases: , advantages and disadvantages of laser cleaning, effectiveness of laser cleaning

- Laser cleaning for removing contaminants from vinyl surfaces - 27 May 2024

- Laser cleaning: A precise method for removing contaminants from solar panels. - 27 March 2024

- What is technical debt and how to deal with it - 28 December 2023